i am mr aosiman tuohesun , from yiwu oou import and export co.,ltd , the company founder.

我是义乌噢欧进出口有限公司的奥斯曼托合荪先生,该公司创始人。

On a sunny day, filled with curiosity and anticipation, I stepped into Pujiang County, Jinhua, Zhejiang Province. There lies a well – known factory specializing in the production of fridge magnets, keychains, and barbells. Initially, I thought this was just an ordinary visit, but I was deeply impressed by the industrial charm that unfolded before my eyes.

As soon as I entered the factory gate, I could feel the busy yet orderly atmosphere. The factory covers a large area, with the main building being an impressive five – story building. Each floor houses different production processes, functioning like a precise industrial machine.

一个阳光明媚的日子,满怀好奇和期待,我走进了浙江省金华浦江县。这里有一家知名工厂,专门生产冰箱磁铁、钥匙扣和杠铃。起初,我以为这只是一次普通的参观,但眼前展现的工业魅力让我深受感动。

一进工厂大门,我就能感受到忙碌而有序的氛围。工厂占地广阔,主楼为一栋令人印象深刻的五层建筑。每层楼都设有不同的生产工艺,像精密的工业机器一样运作。

Entering the first floor, the area of base – coat machinery comes into view. The huge base – coat machines are neatly arranged. Despite their large size, they operate with extreme precision. These machines mark the first step in product production, tasked with applying a uniform base – coat to products like fridge magnets and keychains. The base – coat not only protects the product’s material but also provides an excellent foundation for subsequent printing and decoration. Workers skillfully operate these machines, placing the items to be processed onto the conveyor belt. Then, the machines start working methodically. The base – coat is evenly sprayed onto the product surface, forming a thin protective film that glows faintly under the light.

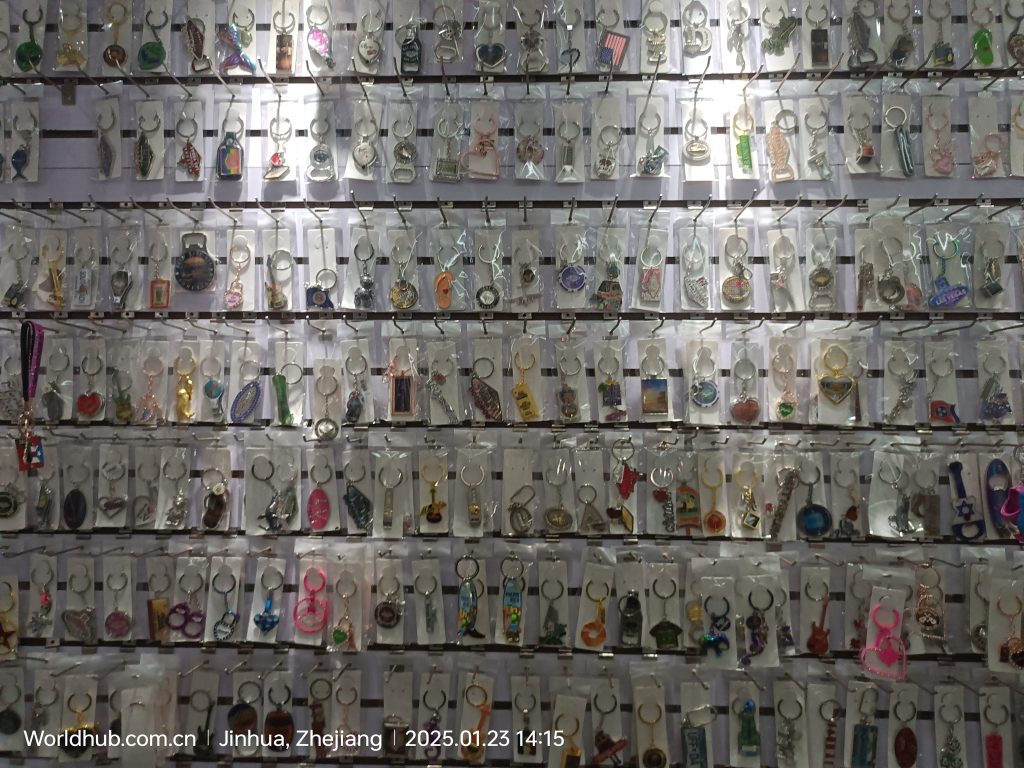

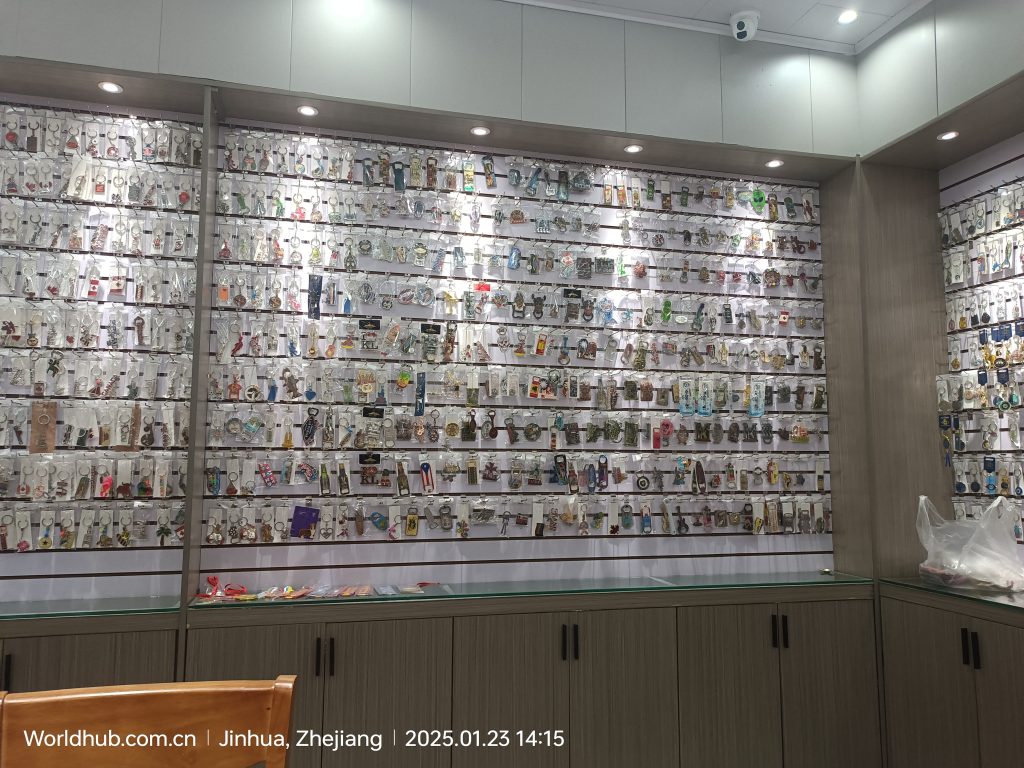

Going up the stairs to the second floor, we arrive at the sample exhibition room. Stepping into this room is like entering a dazzling small world. The walls are adorned with a wide variety of fridge magnets, ranging from cute cartoon characters to exquisite landscape patterns, from local cultural symbols to popular film and TV animation peripherals. Each fridge magnet is exquisitely made, with vivid colors and meticulous attention to detail. In the display cabinets, there are keychains of various styles. There are simple and stylish metal keychains engraved with delicate patterns, and creative silicone keychains in different shapes, some resembling small animals, others like fruits, vivid and lifelike. There are also barbell – model keychains familiar to fitness enthusiasts. Although small, they perfectly replicate the real appearance of barbells. Besides fridge magnets and keychains, some barbell samples produced by the factory are also displayed in the exhibition room. These barbells have a smooth surface, uniform color, and clear weight markings, demonstrating the factory’s strict control over quality.

The third floor is the core area of the production line, where a bustling production scene unfolds. Workers are busy at their respective posts, attentively completing each production step. In the area for producing fridge magnets, workers precisely paste the printed patterns onto the products that have already been coated with the base – coat, and then perform a laminating process to ensure the durability of the patterns. On the keychain production line, the machines stamp metal materials into various shapes, and then through multiple processes such as polishing and buffing, the rough metal blanks gradually transform into shiny and exquisite keychains. In the area for producing barbells, it is a different scene. Large forging equipment heats and forges the metal raw materials to form the shape of barbells. Then, they are finely processed and adjusted to ensure that the weight of each barbell is accurate and its balance performance is good.

The fourth floor is the quality inspection office, which is the last line of defense for product quality. Quality inspectors sit at their workbenches, carefully examining each product. They use professional testing tools to check the pattern clarity and color saturation of fridge magnets, inspect whether there are flaws on the surface of keychains and if the plating is firm, and test whether the weight error of barbells is within the allowable range and whether the anti – slip treatment on their surface meets the standards. Products that do not meet the quality standards are labeled and uniformly reworked. Here, I deeply felt the factory’s emphasis on product quality, leaving no detail overlooked, just to ensure that every product delivered to consumers is flawless.

Going up to the fifth floor, this is the management and technology research and development area of the factory. Looking out of the window, you can overlook the entire production scene of the factory, feeling the powerful force of industrial production. The management team formulates production plans and coordinates the work of various departments here to ensure the smooth progress of the production process. And the technology R & D personnel focus on the research and development of new products and the improvement of production processes. They constantly explore new materials and technologies, striving to keep the factory’s products competitive in the market.

During the visit, I not only witnessed how these small items were transformed from raw materials into exquisite products step by step but also felt the hard work and persistent pursuit of quality behind the factory. Each fridge magnet, each keychain, and each barbell embodies the wisdom and sweat of the workers. They are not just commodities but also the crystallization of industrial art. This trip to the factory in Pujiang gave me a new understanding of the manufacturing industry and made me deeply realize the important position of China’s manufacturing industry in the global industrial chain.

进入一楼,底漆机械区映入眼帘。巨大的底漆机整齐地摆放着。尽管体型庞大,它们的作极为精准。这些机器标志着产品生产的第一步,任务是为冰箱磁铁和钥匙扣等产品均匀地涂上底层。底漆不仅保护了产品的材料,还为后续的印刷和装饰提供了极佳的基础。工人熟练地作这些机器,将待处理物品放上传送带。然后,机器开始有条不紊地工作。底层涂层均匀喷涂在产品表面,形成一层薄薄的保护膜,在灯光下微微发光。

上楼到二楼,我们来到样品展览室。走进这个房间,就像进入了一个耀眼的小世界。墙上挂满了各种冰箱磁铁,从可爱的卡通人物到精致的风景图案,从本地文化符号到流行的电影和电视动画周边。每一个冰箱磁铁都做工精致,色彩鲜艳,细节一丝不苟。展示柜里摆放着各种风格的钥匙扣。有简洁时尚的金属钥匙扣,雕刻着精致的图案,还有创意十足的硅胶钥匙扣,形状各异,有的像小动物,有的像水果,鲜艳而栩栩如生。还有杠铃款式——健身爱好者熟悉的型号钥匙扣。虽然体积小,但它们完美还原了杠铃的真实外观。除了冰箱磁铁和钥匙扣外,工厂生产的一些杠铃样品也陈列在展览室内。这些杠铃表面光滑,颜色均匀,重量标记清晰,体现了工厂对质量的严格控制。

三楼是生产线的核心区域,这里展开着繁忙的制作场景。工人们忙于各自岗位,专注地完成每一个生产步骤。在生产冰箱磁铁的区域,工人会精确地将印刷图案粘贴到已涂有底漆的产品上,然后进行覆膜工艺以确保图案的耐久性。在钥匙扣生产线上,机器将金属材料冲压成各种形状,然后通过抛光和抛光等多重工艺,粗糙的金属坯料逐渐转变为光亮精致的钥匙扣。在杠铃生产领域,情况则截然不同。大型锻造设备加热并锻造金属原料,形成杠铃的形状。然后,它们会经过细致处理和调整,以确保每个杠铃的重量准确且平衡性能良好。

四楼是质量检验办公室,是产品质量的最后防线。质量检查员坐在工作台前,仔细检查每一件产品。他们使用专业测试工具检查冰箱磁铁的图案清晰度和色彩饱和度,检查钥匙扣表面是否有缺陷,电镀是否坚实,测试杠铃的重量误差是否在允许范围内,以及表面防滑处理是否符合标准。不符合质量标准的产品会被贴标签并统一重新加工。在这里,我深刻感受到工厂对产品质量的重视,每一个细节都被忽视,确保每一件交付给消费者的产品都无可挑剔。

上到五楼,这里是工厂的管理和技术研发区。望向窗外,你可以俯瞰整个工厂的生产场景,感受到工业生产的强大力量。管理团队制定生产计划,协调各部门工作,确保生产过程顺利进行。技术研发人员则专注于新产品的研发和生产工艺的改进。他们不断探索新材料和技术,努力让工厂的产品在市场上保持竞争力。

在参观期间,我不仅见证了这些小物件如何一步步从原材料变成精致产品,也感受到工厂背后对品质的辛勤努力和坚持不懈追求。每一个冰箱磁铁、每个钥匙扣和每一个杠铃,都体现了工人的智慧与汗水。它们不仅仅是商品,更是工业艺术的凝结。这次浦江工厂之行让我对制造业有了新的认识,也深刻体会到中国制造业在全球产业链中的重要地位。

Leave a Reply

You must be logged in to post a comment.